SOLUTION

WEEE Plastic

Email:

sales@sunkoie.com

WhatsApp:

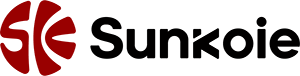

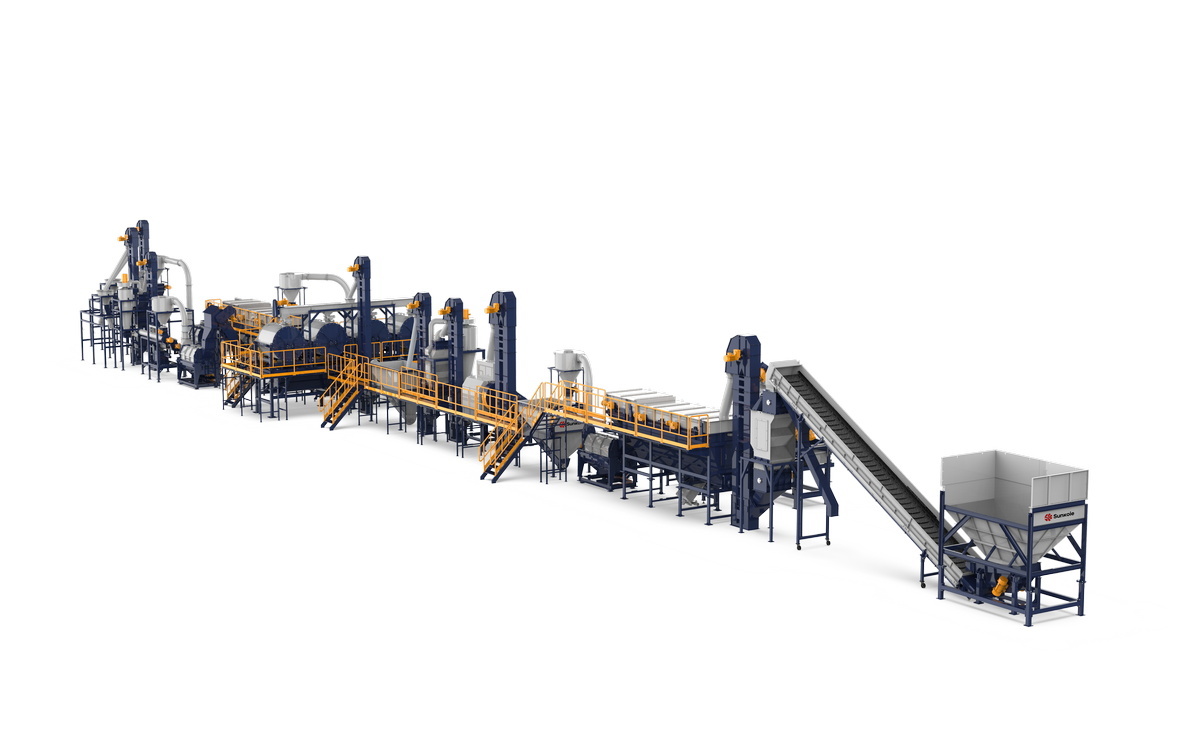

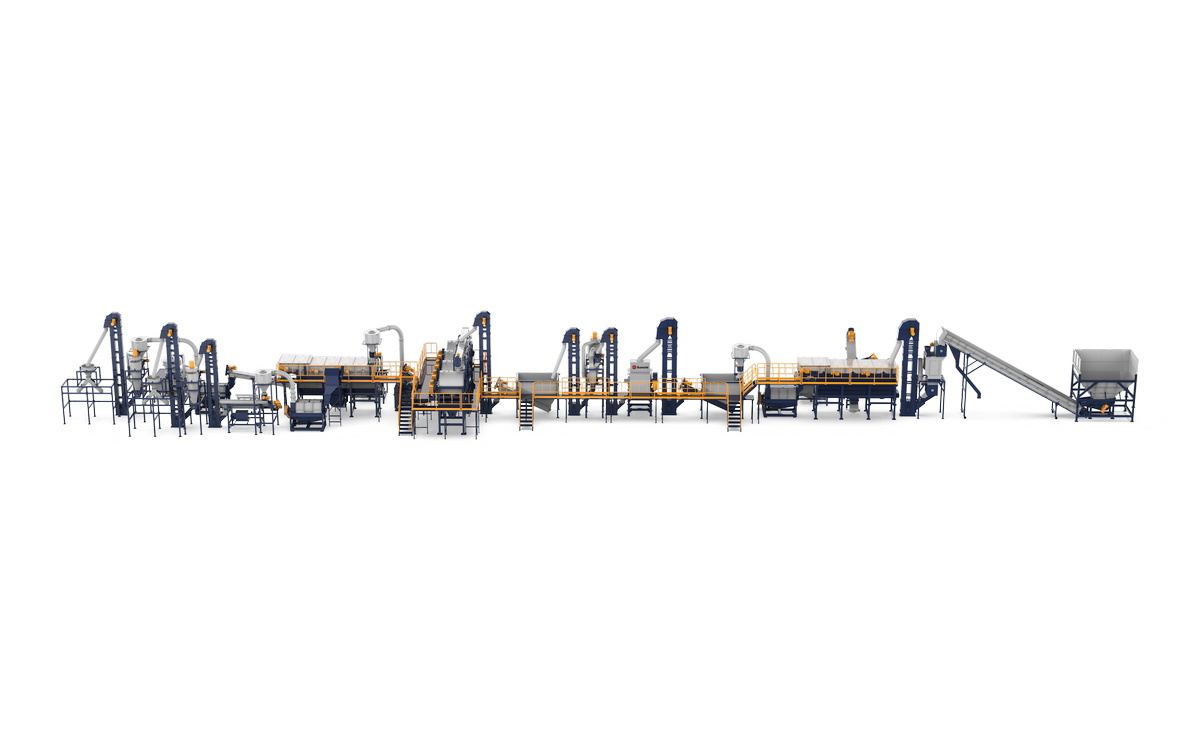

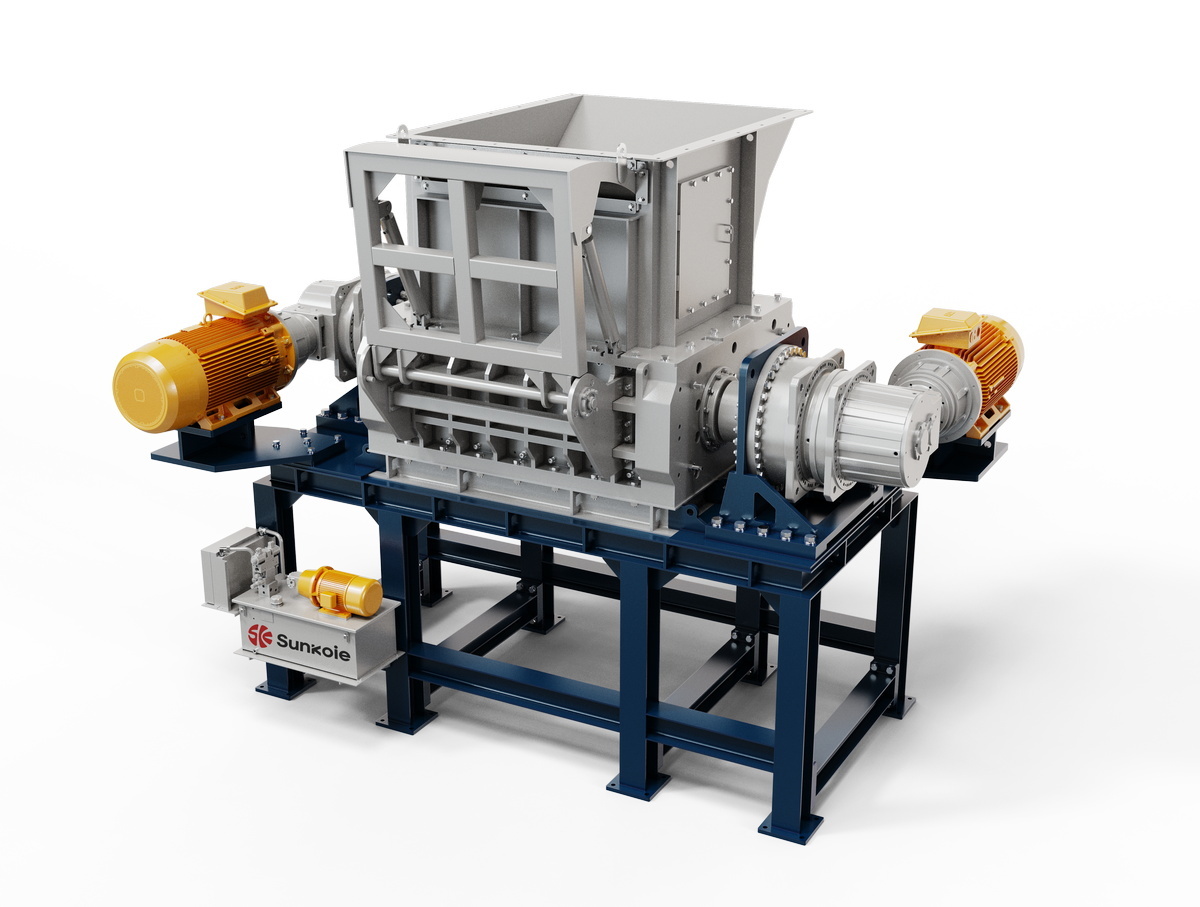

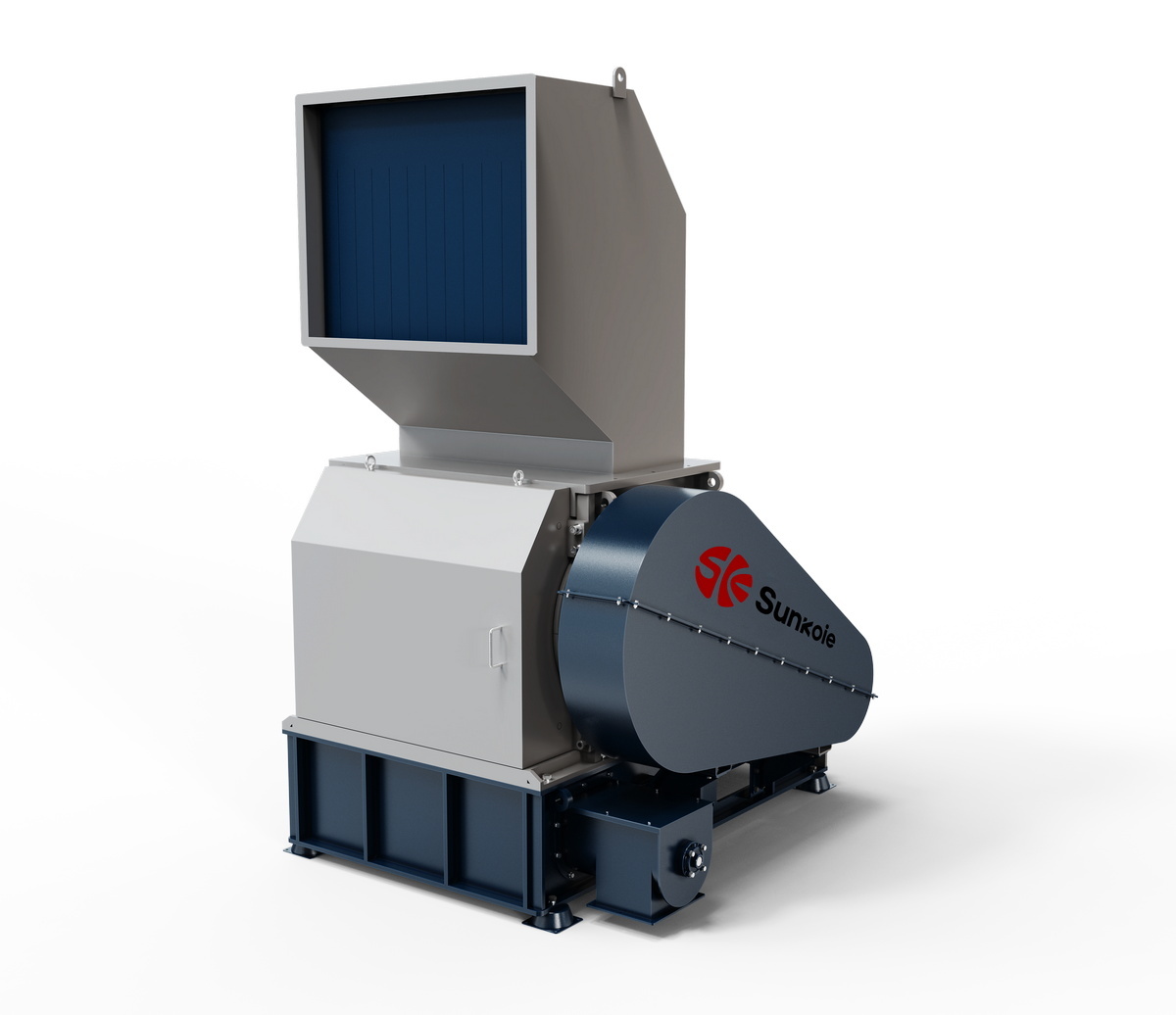

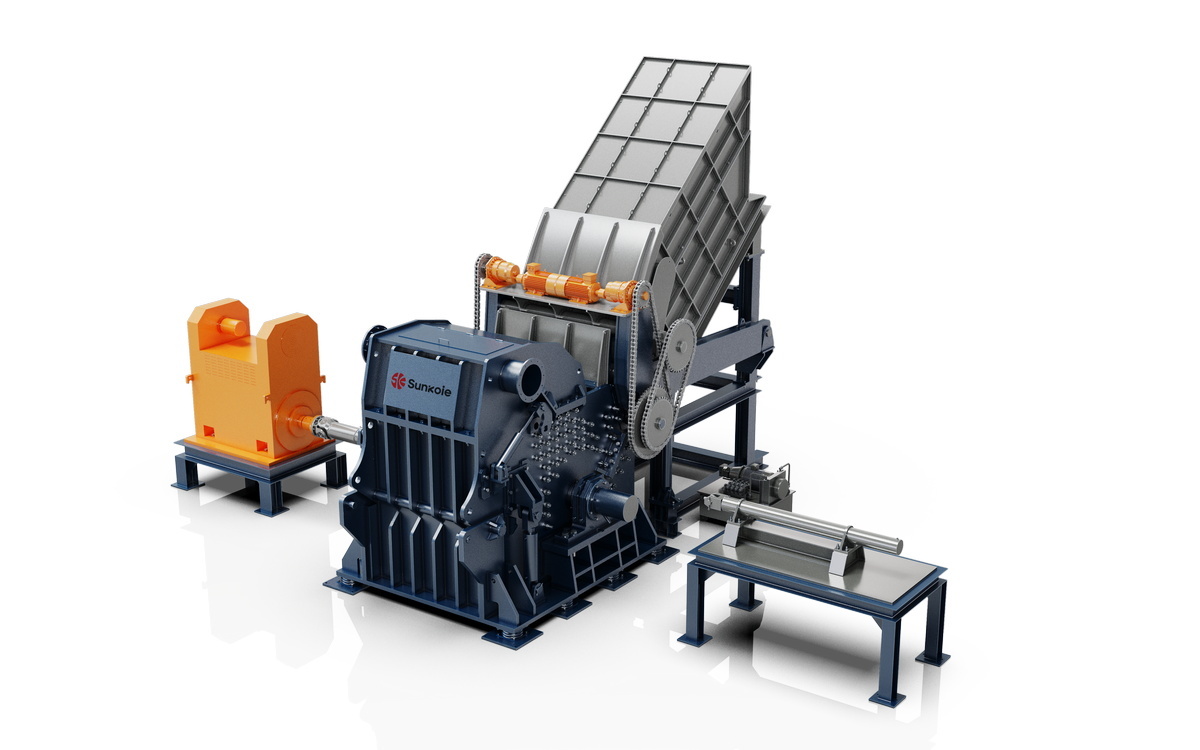

The process begins with a thorough shredding of appliances, after which advanced optical sorting technology is employed to effectively separate metals. In addition, plastics are sorted through a combination of density and optical sorting techniques. To further improve the quality of separation, a hot wash module and a wood/capacitor removal module can be integrated into the system. This meticulous process achieves an outstanding purity level of 98% for copper, aluminum, ferrous metals, and single-stream plastic flakes, thereby meeting the diverse requirements of various customers.

Advantages:

1.98% separation rate

2.Combined with density, optical sorting technology

3.2MT-10MT Capacity

4.Hot wash module enhance the plastic cleanness

Prev -

- Next

Prev -

Next -

Related Products